Time:2023-03-11

Time:2023-03-11

Author:

Author:

Read 345time

Read 345time

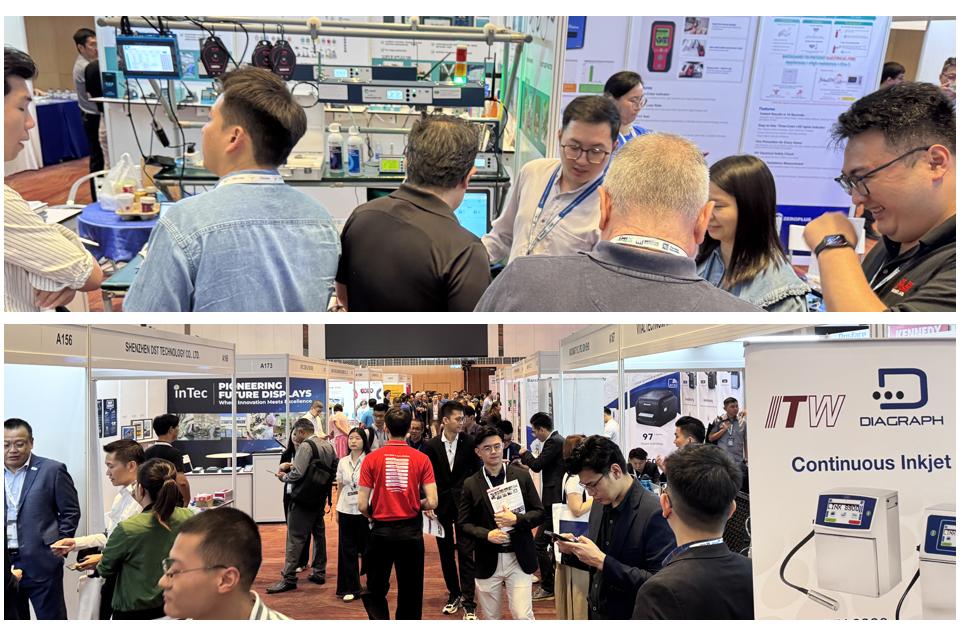

On July 23, 2025, the 4th Electronics Manufacturing Expo Asia (EMAX) officially opened in Penang, Malaysia. BAKON made a strong presence at the event, presenting a newly developed product matrix and ecosystem strategy. Powered by a three-pronged approach of technological barriers, experiential innovation, and precise market positioning, BAKON aims to build differentiated advantages in the professional-grade DIY market.

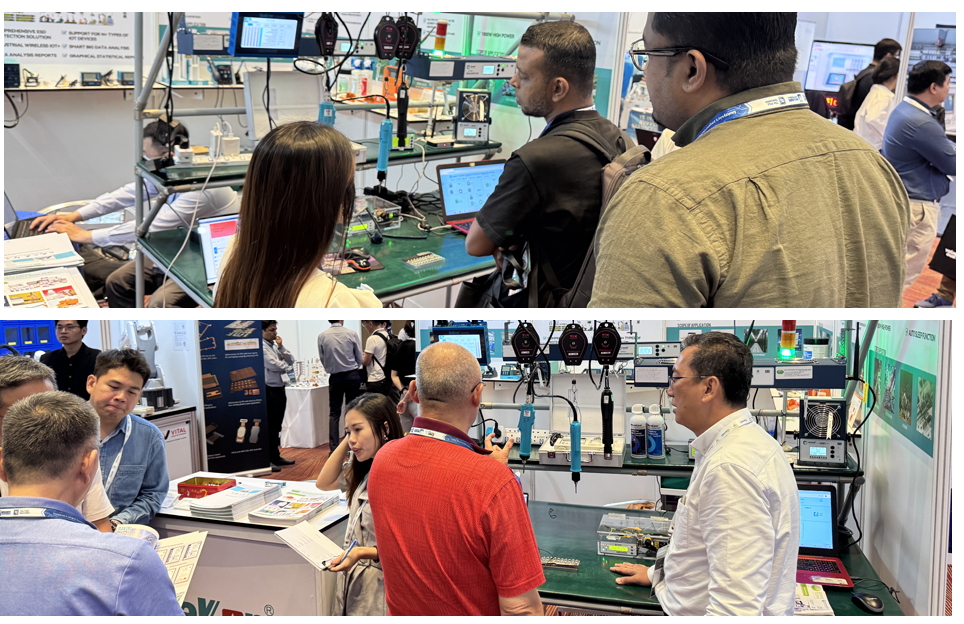

BAKON spotlighted its flagship soldering stations, BK8586MX and BK852MX, featuring its proprietary ±1℃ precision temperature control system. This innovation reduces thermal fluctuation by 60% compared to the industry average—precisely meeting the demands of high-accuracy soldering for electronic components.

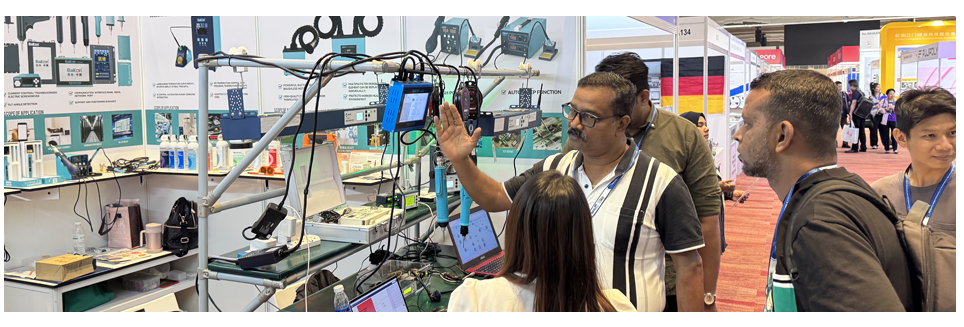

Its modular architecture supports customizable replacements of soldering tips, sensors, and other key modules, delivering a “tool-as-platform” experience that redefines user interaction. Live demonstrations at the booth drew sustained attention from both engineering professionals and buyers.

Addressing the increasing demands of overseas professionals for precision assembly and electronics manufacturing, BAKON introduced two major innovations: an Intelligent Screwdriving System and an Advanced ESD Elimination Solution.

Intelligent Screwdriving System:

The system integrates ±5% high-precision torque control, multi-axis synchronized operation, and real-time cloud-based production data logging. Seamlessly interoperable with the BK212 soldering station, it enables a fully digitized workflow from soldering to screw driving to quality inspection. Compared to traditional manual processes, it improves operational efficiency by 40% and reduces defect rates to below 0.3%.

ESD Elimination Solution:

Combining ion air knives with real-time electrostatic monitoring, the solution achieves a 99.8% static discharge rate without chemical residue—making it ideal for static-sensitive environments. It can be directly embedded into the screwdriving workflow, creating a dual-layer protection system for precision assembly and ESD mitigation.

At the exhibition, the integrated demo of the screwdriving and ESD systems attracted strong interest from local Malaysian industrial zones and Southeast Asian procurement representatives, with over 180 technical consultations recorded per day.

BAKON’s strategy aligns closely with Malaysia’s Digital Free Trade Zone (DFTZ) policy, with a sharp focus on professional DIY users and small-to-medium manufacturers. During the expo, BAKON held discussions with the Penang Industry Association and MIMOS, clearly outlining its transformation from “cost-effective tools” to a “professional-grade ecosystem.”

The company reached preliminary distribution agreements with three key partners in Southeast Asia and plans to officially launch the BK212 Ecosystem Kit in Q4 2025, targeting core markets including Malaysia and Singapore.

Leveraging EMAX Penang 2025 as a strategic platform, BAKON is advancing from a single-device supplier to a provider of complete professional creation solutions, driven by its ±1℃ precision thermal control and a holistic “tools + accessories + software” ecosystem.

This strategic leap not only redefines the global professional DIY tool market but also aligns with ESG trends through its low-power product line—achieving up to 40% energy savings compared to conventional soldering stations. BAKON is injecting Chinese innovation into Southeast Asia’s electronics manufacturing landscape.

Looking forward, BAKON will continue to build on technological barriers and empower through ecosystem collaboration, leading the global tool industry from functional competition to value co-creation in a new era of innovation.

Information Recommending

Information Recommending